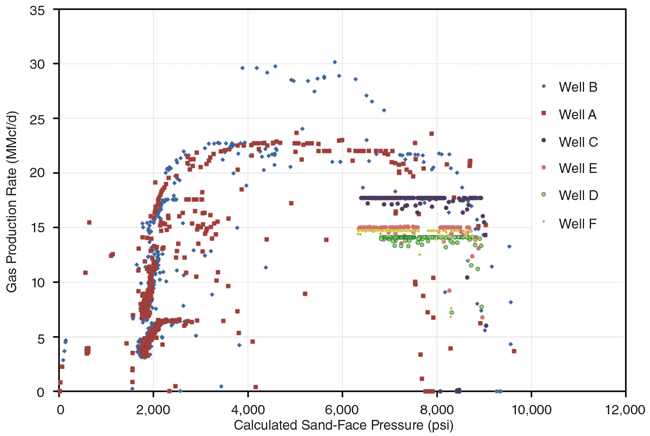

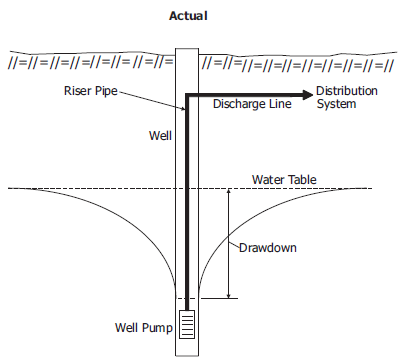

Surface rate measurement errors can be caused by a variety of sources. Models for critical flow velocity needed to mobilize proppant from fractures. Measurement errors cause significant ambiguity in well performance analysis and can mask reservoir responses. Once the initial target rate and choke size is established and the well is brought online, the next step is to assess data quality and identify possible measurement errors. Some wells produce oil, some produce gas, but all wells produce data, and those data need to be of the highest quality possible to accurately assess well performance in real time and to optimize the drawdown strategy. Garbage In, Garbage OutĪfter the initial flow rate of a well is determined, an initial choke size can be selected to bring the well online without mobilizing proppant from the fractures. By simply flowing the well a bit more slowly in the beginning, sand volumes and the associated equipment costs to handle these solids can be significantly reduced and well performance can be improved. This helps determine the initial target rate and choke size so proppant is not washed out of the fractures when the well is first brought online.Īs confinement stress increases during IP, and more of the lateral begins to contribute to total flow, the well can then start to be flowed more aggressively. Revo uses an algorithm to calculate the minimum mobilization velocity of proppant in the fractures when confinement stresses are low at the beginning of flowback. This adds additional costs to handle excessive sand rates at surface, and this approach has been shown to decrease well performance. Many operators utilize additional sand management equipment during flowback to handle high sand volumes believing that high flow rates create better wells. Improvements in well performance have been observed in the field when managed pressure drawdown strategies are employed. Significant research has been conducted on flowback optimization and diagnostic techniques. The comparisons have consistently shown Revo’s drawdown optimization workflow improves well performance compared to an aggressive flowback strategy. These comparisons were done on optimized wells versus wells that employed aggressive flowbacks-and the wells had similar completion and reservoir parameters. Side-by-side comparisons have been completed in every major unconventional basin. The workflow incorporates a proppant mobilization model, real-time well performance visualizations and specialized diagnostic techniques. Revo Testing Technologies has developed an integrated workflow that has been successfully utilized on more than 500 unconventional wells to optimize drawdown strategies during IP. A comparison of cumulative oil production per foot of lateral for two Permian Basin wells landed in the same zone, less than a mile apart, with similar completion design and lateral orientations or no offsets.

A real-time workflow must be used to evaluate flowback data to optimize the drawdown strategy so operators can maximize the production of each well, in the shortest amount of time, all without damaging the reservoir or completion. This approach is often derived from rules of thumb or simplified diagnostics that fail to capture the true effects of drawdown on well performance.

Many operators tend to either flow wells too aggressively or too conservatively. The data collected during this early-time flowback period offers one of the first glimpses of valuable information that helps to evaluate well performance and reservoir responses. Drawdown management during the IP period-or flowback-is an often overlooked means of improving well performance. Much of that improvement is centered on well spacing, completion designs and surface efficiency. Now more than ever, operators are focused on methods of improving well performance to reduce costs and increase production.

0 kommentar(er)

0 kommentar(er)